De ontwikkelingen rondom AM staan niet stil

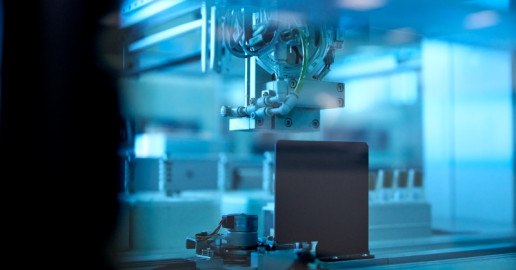

Grote kans dat je als technisch professional of manager al kennis hebt gemaakt met Additive Manufacturing (AM). Waarschijnlijk heb je zelfs al ervaring opgedaan met het 3D printen van prototypes, onderdelen of kleine series van producten. De ontwikkelingen rondom AM staan echter niet stil en je bent benieuwd hoe je hier nog meer uit kunt halen. Het experimenteren met 3D-printen en het uitvoeren van losse printopdrachten was interessant en leerzaam maar wat als je AM nu echt wilt integreren in je engineering- en/of productieproces?

Zet de volgende stap met Additive Manufacturing

Tijdens AM for Production op 3 oktober ontdek je welke voordelen en kansen er zijn om Additive Manufacturing toe te passen als productietechnologie. De focus ligt op de praktische en technische toepassing en wat komt er bij kijken. Ook ontdek je de nieuwste technische ontwikkelingen, voorbeelden van business cases en leer je welke kennis en vaardigheden er nodig zijn om concreet met AM aan de slag te gaan.

- 12 sprekers in het congres delen hun inhoudelijke kennis, ervaringen, praktijk- en business cases en tips & tricks om AM als productietechnologie in te zetten

- 20 exposanten staan voor je klaar om je vervolgens te helpen bij de toepassing en uitvoering in jouw bedrijf

Blijf op de hoogte!

Mikrocentrum organiseert diverse evenementen, zoals AM for Production, en opleidingen rondom het thema Manufacturing Technology. Wil je op de hoogte gehouden worden van onze activiteiten? Meld je hier aan voor de nieuwsbrief.

Mediapartners

Exposeren

Bekijk de mogelijkheden om jouw bedrijf en/of innovatie onder de aandacht te brengen bij hightech- en maakbedrijven die productie op basis van Additive Technologieën willen ontdekken

Ja, ik heb interesse in exposeren

Locatie en contact

Mikrocentrum

De Run 1115

5503 LB Veldhoven

Nederland

Bart Kooijmans

Programmamanager Evenementen (Precisiebeurs, AM for Production)

Mis AM for Production niet!

Tijdens AM for Production ontdek je welke voordelen en kansen er zijn om Additive Manufacturing toe te passen als productietechnologie.